Smart Warehousing Software Application Services

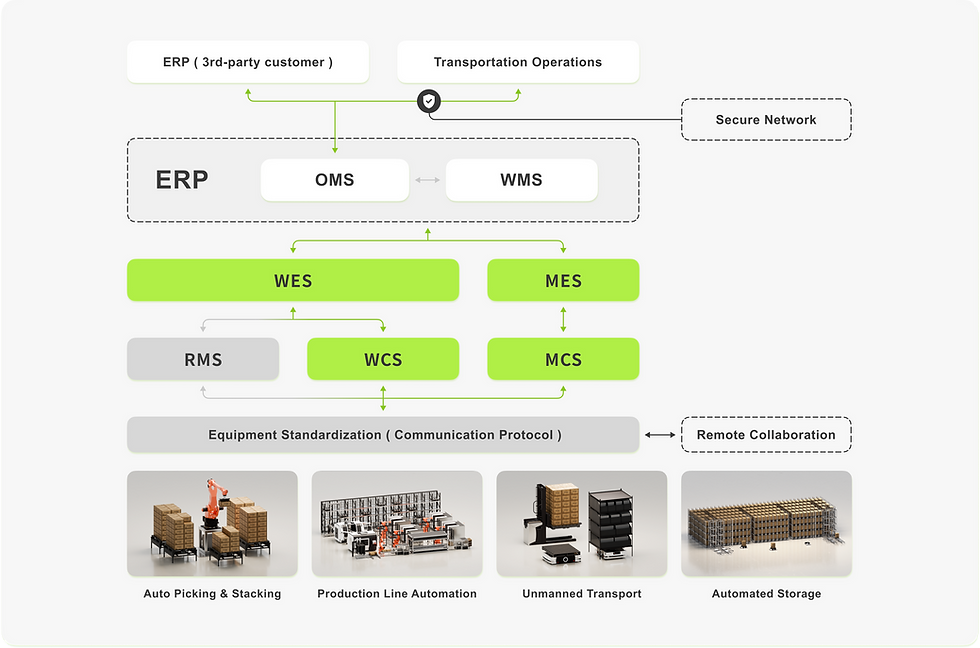

A software system that provides global scheduling optimization and real-time decision-making

Connect devices and systems to work together

Cross-system connection (WMS, ERP), equipment integration, including automation peripherals, Robot, ASRS, AGV

Boosting efficiency from production to logistics

Helping enterprises optimize operations from planning to maintenance with advanced logistics automation solutions.

Flexible introduction of modular architecture

Modular platform flexibly expanding from planning to operation, effectively meeting diverse production needs.

Smart Warehousing Execution System

Integrate automation equipment and on-site operation systems to help companies achieve efficiency and smooth operations and improve overall operational stability.

Covers the following 5 major systems

自動揀貨堆棧

智慧揀選堆放,穩定高效無人化

自動揀貨堆棧

智慧揀選堆放,穩定高效無人化

自動揀貨堆棧

智慧揀選堆放,穩定高效無人化

自動揀貨堆棧

智慧揀選堆放,穩定高效無人化

自動揀貨堆棧

智慧揀選堆放,穩定高效無人化

Goods-to-Person System

— Goods arrive at the station automatically, improving efficiency and reducing movement —

AGV automates transport, reduces labor

Materials are delivered directly to workstations by automated guided vehicles (AGVs), completely removing the need for manual searching and transport. This automation greatly streamlines workflows and lowers labor costs.

Smart dispatch boosts delivery speed

The system automatically schedules tasks based on orders, significantly improving picking efficiency while reducing errors and minimizing personnel movement. It is widely used in smart warehousing and production workflows.

AS/RS

Four-way shuttle storage system

— Flexible shuttle operation, high-density automatic storage —

Flexible shuttle system for dense storage

The four-way shuttle moves in all directions—forward, backward, left, and right—shuttling flexibly in dense storage and automating inbound and outbound operations.

Integrated system for space optimization

Centralized management boosts warehouse automation and space efficiency, ideal for space-limited sites with high storage needs and support for multi-level vertical expansion.

Automatic Pick and Stack System

— Intelligent picking and stacking, stable, efficient and unmanned —

Automatic picking and sorting process

Combining intelligent picking modules with automated equipment like robotic arms, the system automatically picks items by order requirements and performs sorting, stacking, and precise placement efficiently.

Visual recognition fits shipping needs

Integrated with visual recognition and precise positioning, it handles various material shapes and sizes, enabling a fast, stable, and fully unmanned process ideal for high-frequency, diversified shipping scenarios.

Smart Production Line Collaboration System

— Multi-machine collaboration, stable and seamless operation —

Collaboration between different machines, connecting cross-site processes

Integrate info from automated production equipment like CNC machines and handling modules, enabling cross-device scheduling and synchronized operation to bridge gaps between machines and the shop floor.

Dynamic scheduling improves production line resilience and performance

The system dynamically adjusts operation rhythm based on detailed production plans and real-time data inputs, minimizing production interruptions, enhancing line smoothness, and improving overall capacity utilization.

Visual management dashboard system

— Global data visualization, real-time control and decision-making —

The operations dashboard monitors the entire site view

The visual dashboard system integrates on-site equipment, work order progress, warehouse status, and key performance metrics, displaying all information in real time through a war room-style interface for clear and instant visibility.

Data-driven decisions accelerate on-site responses

Managers use the interactive graphical dashboard to monitor utilization rates, production efficiency, and alarms, enabling faster and smarter decisions while building a truly data-driven on-site operational management model.

Intelligent Automation System Integration

We integrate automation, control, and vision systems to build flexible, modular smart production lines. Whether new or upgraded, they adapt to different processes and improve flexibility and stability.

Smart production line construction

Integrate automation (e.g. robots, handling modules) and control systems to build flexible, scalable smart lines. Ensure stable software via device connections and data flow.

Smart Vision Application

Integrate industrial cameras and image recognition technology to automate tasks such as dimension measurement and defect detection, significantly enhancing the accuracy and responsiveness of quality control.

Equipment data integration

Edge devices (e.g. Box PCs, IoT gateways) collect machine and energy data for real-time monitoring and analysis, enabling process optimization, energy management, and predictive maintenance.

Smart scheduling to improve delivery efficiency

Automatically schedules by demand, improves picking, and reduces errors and movement. Common in smart warehousing and production lines.

AGV automated transportation, replacing manual labor

AGVs deliver required materials directly to workstations, replacing manual search and transport.

Goods-to-Person System

— Automated item delivery to station, reducing movement and increasing efficiency —

Integrated system improves space efficiency

Centralized management boosts automation and space use. Ideal for compact sites with high storage needs and vertical expansion.

Flexible shuttle high-density storage

The four-way shuttle navigates dense storage and handles inbound and outbound tasks to boost efficiency.

AS/RS

Four-way shuttle storage system

— Flexible shuttle operation, high-density automatic storage —

Visual recognition to meet diverse shipping needs

With visual recognition and precise positioning, it handles diverse materials efficiently, ensuring stable, fast processing for high-frequency, varied shipping.

Automatic picking and sorting

Combining smart picking modules with robotic arms, it picks items by order and performs sorting, stacking, and placement with precision.

Automation System

— Warehouse automation for stable and efficient operations —

Dynamic scheduling enhances line resilience and efficiency.

The system adjusts operations using MES plans and real-time data, reducing interruptions and improving flow and capacity.

Cross-machine collaboration linking processes across sites

Integrate equipment data (CNC, handling) for cross-machine scheduling, synchronized operation, and bridging system-site gaps.

Smart Production Line Collaboration System

— Multi-machine collaborative operation, stable operation and smooth connection —

Data drives decision making and accelerates on-site response

Managers use the dashboard to view utilization, efficiency, and alerts, enabling quick decisions and data-driven on-site management.

Battle situation dashboard, monitoring the entire scene

The dashboard shows real-time equipment, work, and warehouse data in a war room view for full site visibility.

Visual management dashboard system

— Global data visualization, real-time control and decision-making —

Advantech Products and Services